Industrial image processing

- Development and production of vision systems

- Our company has been a Cognex systems integrator partner for 12 years

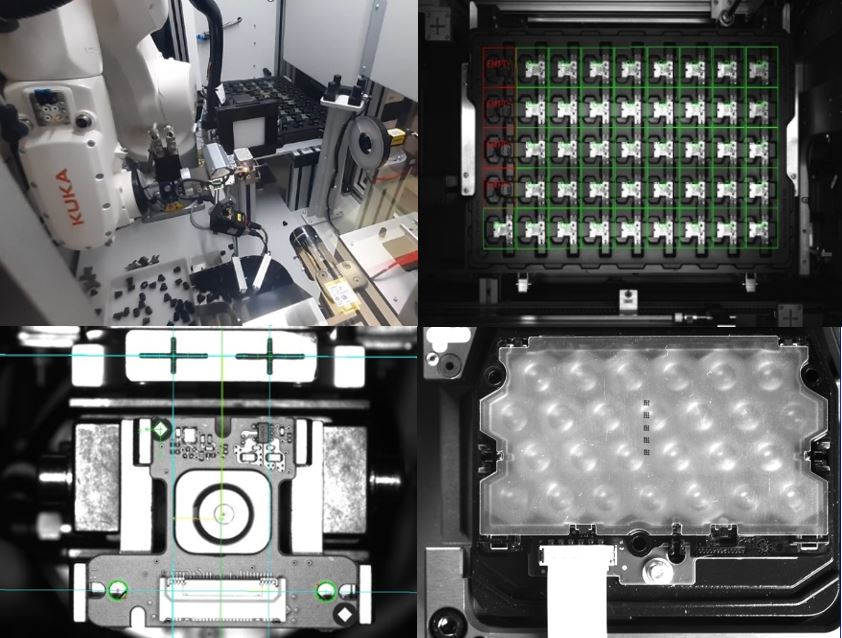

- 2D and 3D vision solutions for quality control, process control, robot control

- 15 years experience in design, programming and commissioning of vision systems

- 30 years experience in industrial automation

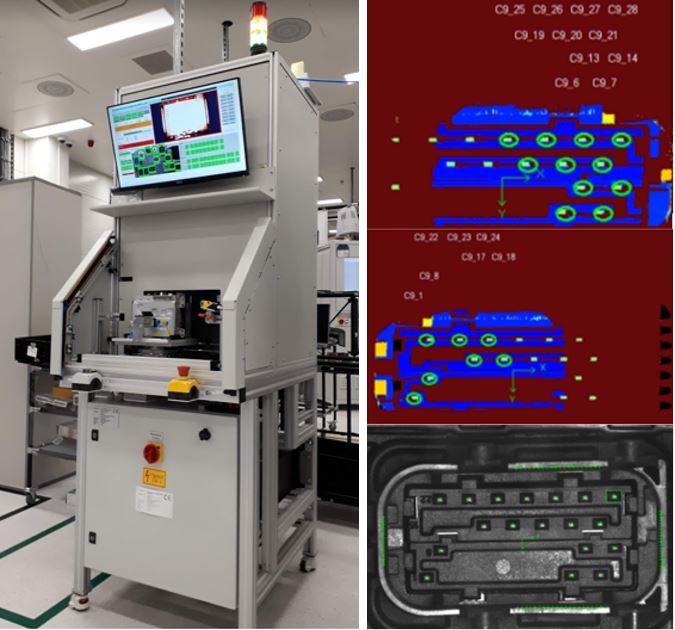

Design, manufacturing, integration

- Design and manufacture of measuring and control stations based on image processing

- Vision cells, target machines to be integrated into production lines

- ISO 9001:2015 certification for the manufacture of custom vision machines

- Design and construction of vision systems for existing or new machines

Software development

- Vision software development with Cognex In-Sight/VisionPro/ViDi tools

- Development of custom image processing algorithms and procedures

- Barcode, character reading control systems

- Image analysis systems generated from product specification data

- Development of vision based measurement data acquisition systems, MES communication

- PLC and microcontroller based control programming

Instrumenting, monitoring

- High reliability field measurement systems, data loggers

- Aviation fuel additive equipment

- Web-based SCADA systems, displays

- Customer specific data converter and data concentrator modules, software

- Measurement and control systems for explosion proof environments

Robot positioning, position measurement

- High precision positioning with PatMax algorithm

- Elimination of distortions due to lens or viewing angle by non-linear calibration

- Simultaneous quality control and position testing

- Handling changing light conditions

- 3D solutions, bin-picking tasks

Connector and pin check

- Pin deflection measurement with +/- 0.01 - 0.02 mm accuracy

- Pin length measurement with +/- 0.02 mm accuracy

- Pin measurement with connector insertion compensation

- Connector damage inspection with combined illumination

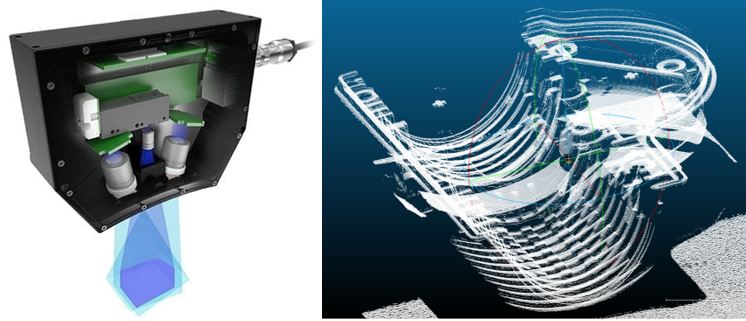

Geometric measurement of products with 2D and 3D imagers

- Non-contact geometric checks and measurements integrated in the production line

- High resolution 2D cameras, telecentric lenses, structured illumination

- Factory calibrated high accuracy 3D measurement scanners, snapshot cameras

- Use of multi-vendor 3D imaging tools

- Combination of 2D and 3D measurements

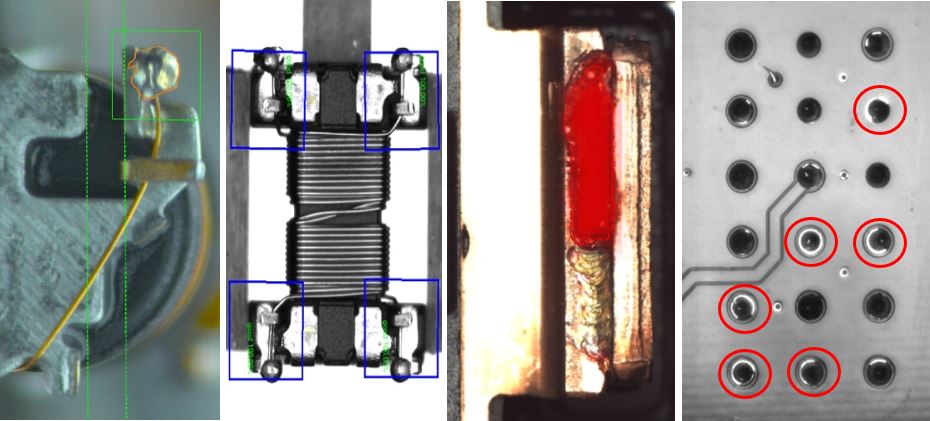

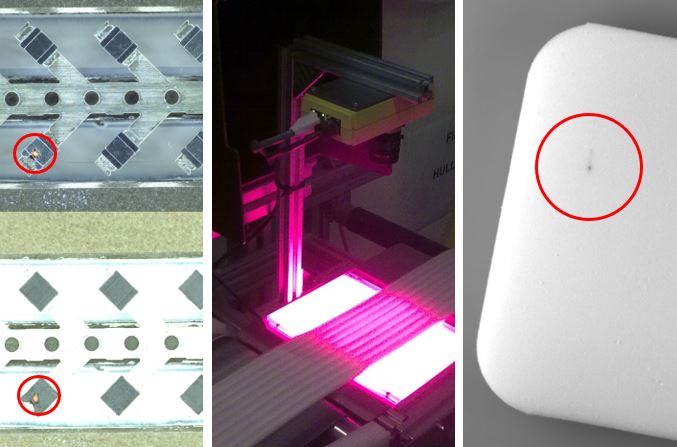

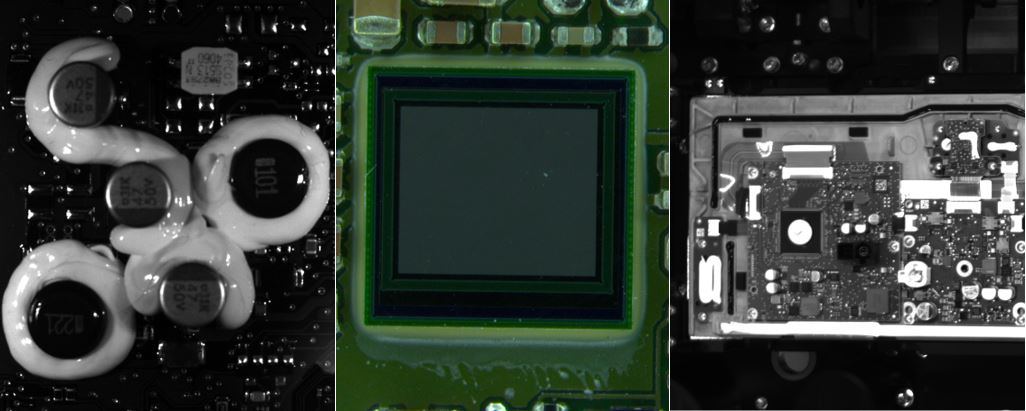

Soldering, welding test

- Verification of weld shape and errors using ViDi (deep-learning) algorithms

- Checking the existence and completeness of soldering

- Inline inspection stations with macro lenses, special illumination

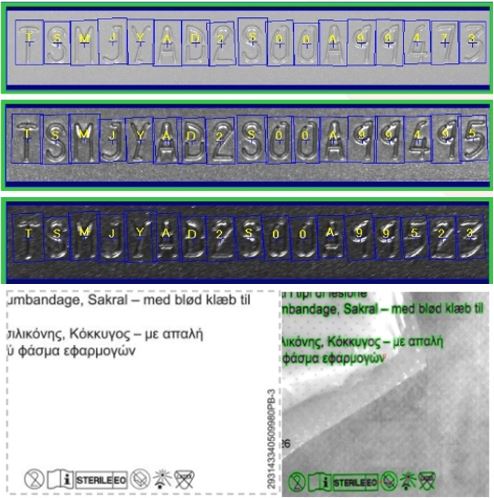

Text and label inspection

- OCR verification with the Cognex OCRMax algorithm

- DeepLearning based caption reading (ViDi Blue tool) for checking difficult to read captions

- Sample (print image) verification with adjustable tolerances

- Inscription, code validation based on PLC, database or MES data

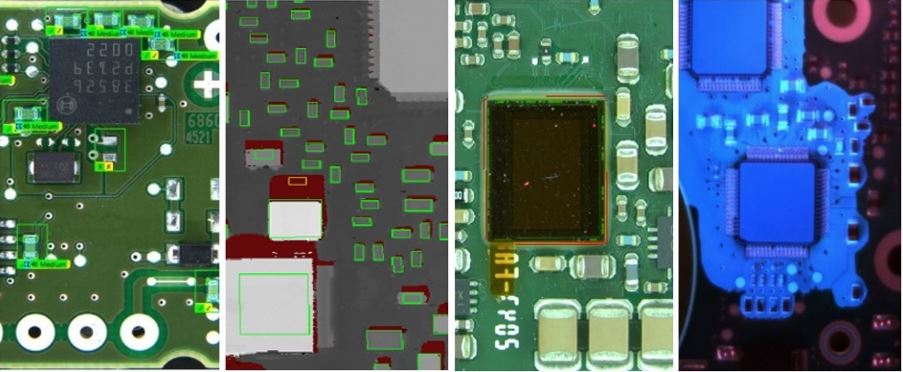

PCB inspections

- Component insertion check (existence, polarity, type check)

- Component position check

- UV reagent varnishing check

- Check adhesive application

- Contamination, damage inspection

Inspection for damage, surface defects, dirt

- High-speed testing, even while the material is moving

- Rule-based and deep-learning vision algorithms

- Detection of colour, texture or pattern variations with tolerance limits

- Surface inspection, damage inspection

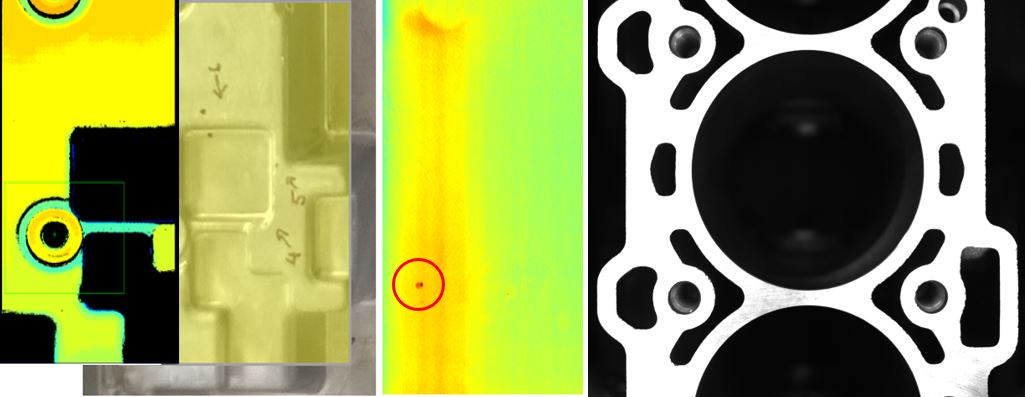

Flatness measurement, surface defect inspection, porosity testing

- 3D flatness measurement with an accuracy of up to 1 µm

- Detection of local surface irregularities with an accuracy of 10-30 µm

- Polished surface porosity testing with special illumination or 3D scanner

Bonding, sealant testing

- Checking the application of adhesive, sealant

- 3D tests to check quantitative data

- Trace inspection

- Checking "forbidden" and "mandatory" areas, adjustable thresholds

- Special lights for proper highlighting of adhesive